Information Was Provided By The Government of Canada. Read Original Documentation on their website. Keeping The Heat In

Keeping The Heat In

Upgrading windows and exterior doors

Windows and doors can account for up to 25 percent of total house heat loss. Windows and doors can be repaired, however at times it is best to replace them with more energy-efficient models. Proper installation and maintenance also play a key role in saving energy and improving comfort. Learn about upgrading or replacing windows and doors.

Windows

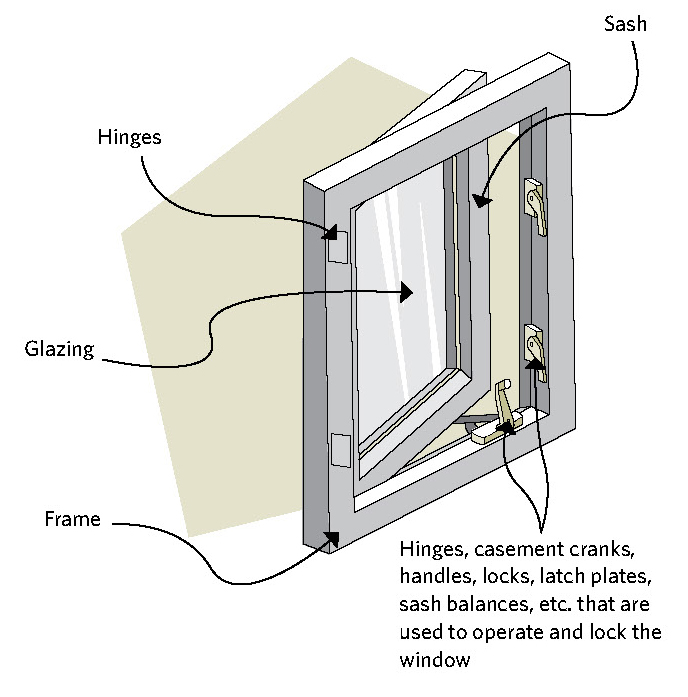

There are a number of options for upgrading the energy efficiency of your windows. Windows can be repaired by servicing hardware such as latches, cranks and locks or retrofitted with caulking and weatherstripping or adding glazing and storm windows. At times the best choice is total window and frame replacement with new, high-performance ENERGY STAR® certified windows or inserts. If the frames are still in good condition, inserts (i.e. new sash and glazing units) can be a good option, especially for homes with heritage status.

Replacing glazing, sashes and windows

Properly installed energy-efficient windows make homes more comfortable by reducing drafts and increasing the temperature of the interior side of the window, reducing condensation. Energy-efficient windows will have many of the following features:

- double-, triple- or even quadruple-glazing

- low-emissivity (low-E) glass

- inert gas, such argon or krypton in the sealed unit

- low conductivity or warm-edge spacer bars

- insulated frames and sashes

- good air tightness

If your inspection has revealed serious problems with a window’s glazing, sash or the entire unit, your best option will be to replace all or part of the window.

For example, if the glazing is only a single pane of glass or is in poor condition, you can buy a new sealed glazing window insert. If the frame is in poor condition, it may be time to replace the unit.

Taking stock

Check each window for signs of damage: rot, mould and/or staining on or around the window, the condition of the glass, putty and paint, weatherstripping and the operation and condition of the hardware. Some windows may need only minor air sealing work, while others require major upgrading or even replacement. Check for air leakage around the frame and at all movable joints. Combine a visual inspection with a test using a leak detector as described in Section 2, “How your house works.”

Condensation problems

Interior surface condensation and frosting are common complaints. Sometimes the problem is light fogging on some windows; at other times, there may be persistent and heavy frost covering the glass. Many homeowners buy new windows only to find that the problem becomes worse because the old, leaky windows actually helped to reduce humidity. The new windows seal the house more tightly, causing a rise in humidity. One solution is to reduce humidity levels in the house.

For more information on moisture and condensation, see Section 2, “How your house works,” and Section 4, “Comprehensive air leakage control.”

Alternatively, you can increase the surface temperature of the window and frame by adding another layer of glazing. New energy-efficient windows are the best solution.

When condensation forms between panes on non-sealed glazing units or storm windows, moist house air has leaked past the inner pane and condensed on the outer pane. Even dry houses can suffer from this type of condensation problem. This problem is common on second storeys where there is more air being pushed out the window because of the stack effect. The solution is to weatherstrip the inner sash to prevent air leakage; make sure that the weep holes on the storm windows, which allow water to escape, are open to the outside.

If condensation occurs inside a sealed double-glazed unit, the problem is best corrected by replacing the glazing unit. Although some specialty companies can refurbish sealed glazing units that have failed, this is considered a temporary fix that will not offer the same original energy efficiency. Check to see if the window is still under warranty.

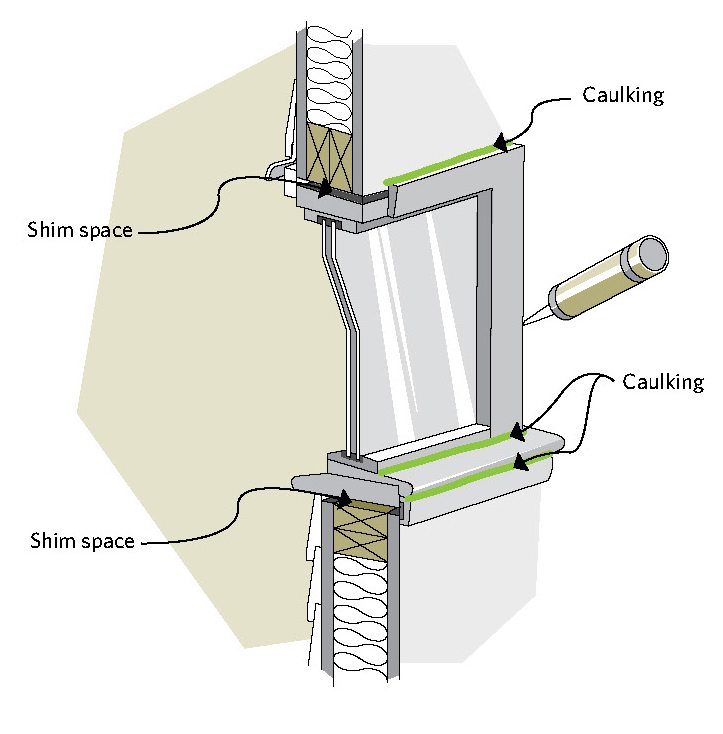

Interior caulking

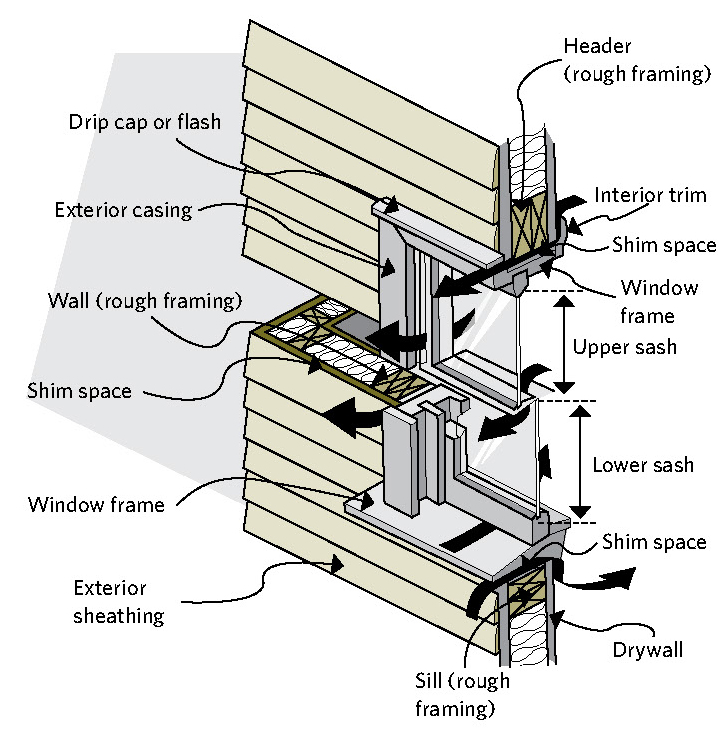

Window air leakage can be reduced by applying a continuous bead of caulk around the window trim where it meets the wall, at the mitred joints of the trim, and between the trim and the frame (see Figure 8-3). Make sure the caulk is intended for indoor use (do not use exterior caulking indoors), can be painted and is of good quality. For more information about caulking products, see Part 3.3, Air barrier materials.

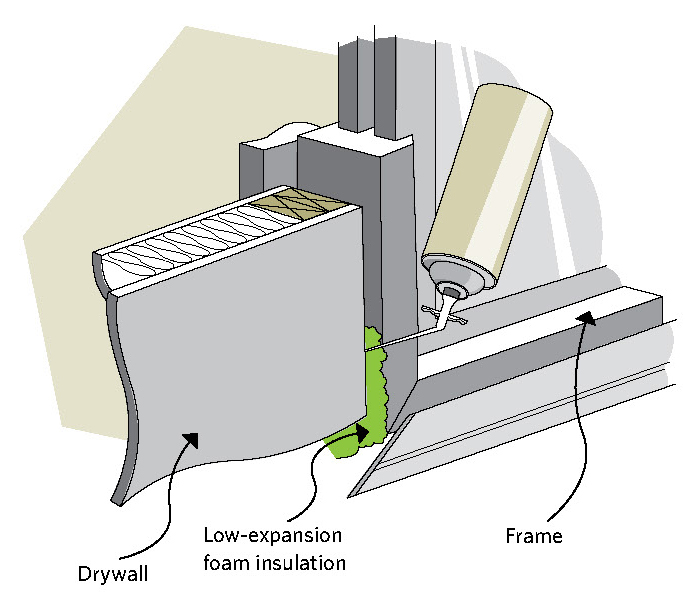

If a window is particularly leaky and the trim can be easily removed and re-installed, remove the trim, add insulation and seal the gap before reapplying the trim. If the gap is small, 6 mm (¼ in.) or less, insulating the gap followed by caulking may suffice. Larger gaps may require either a backer rod with caulking or low-expansion foam (see Figure 8-4).

To further reduce air leakage, apply a layer of red technical tape to cover the joint between the wall and window frame. Ensure that the tape will be hidden by the trim as it cannot be painted and red adhesive may remain after excess tape is removed.

Exterior caulking

Exterior caulking is the last and weakest defence against rain entering a wall from the outside. The best defence against window and door wall leakage includes the following two items:

- properly applied flashing (i.e. top window flashing is underneath the air barrier, while side and bottom flashings are on top of the air barrier)

- a properly detailed drainage plane

Caulking on the outside of a window should be done only after interior sealing is complete. If the exterior is caulked first, it can trap warm, moist air in the wall, which over time, can damage the wall.

Weatherstripping

Weatherstrip windows around the sash to reduce air leakage. If the windows do not have to be opened and do not serve as emergency exits, they can be locked and caulked. Where storm windows are installed, seal the inside window more tightly than the outside window to reduce condensation problems.

TECHNICAL NOTE

Building codes require that every bedroom have at least one window that opens from the inside to allow escape in case of emergency. Be mindful of this requirement before deciding to seal shut certain windows.”

Many types of weatherstripping are available. Table 3-4 lists some of the more common varieties of weatherstripping, though it is certainly not an exhaustive list. Try to visit a window and door supplier that stocks a wide variety of original manufacturer products. For newer windows with built-in weatherstripping that has lost its effectiveness over time, pry out a sample and take it to the window manufacturer or supplier for replacement with the same type. Cheaper products are usually less durable and less effective, so do not choose merely on the basis of cost.

Preparation and installation are important and typically involve the following steps:

- Try to adjust and square windows that are out of alignment.

- Remove old weatherstripping, caulking and blobs of paint from contact surfaces. If the surface is very uneven, apply a bead of caulking under the weatherstripping or fill, sand and paint the surface to make it smooth.

- Clean the surface with a clean cloth and fast-drying mineral spirits or MEK (methyl ethyl ketone).

- Apply the weatherstripping. With doors and windows that are used often, you may want to reinforce the adhesive types with staples.

- Check the window for smooth operation and ensure all hinges, slides and hardware operate freely and correctly.

- Periodically check the weatherstripping for wear.

Double-hung and single-hung windows

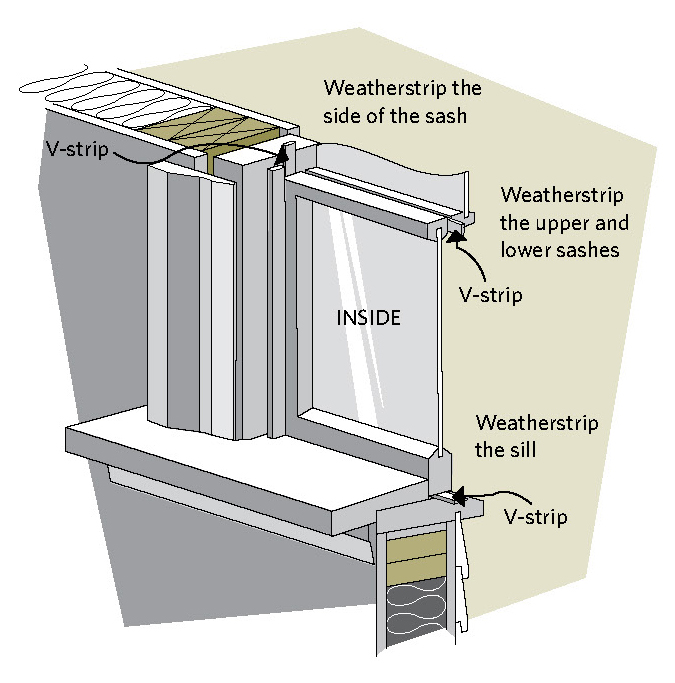

Double-hung and single-hung windows should be weatherstripped on the sides, top and bottom of the moving sash, as shown in Figure 8-5. Caulk air leaks around the fixed portion of the window.

Sides

The thin plastic V-type weatherstripping is a good choice. Open the window and slip the stripping up the crack between the sash and the frame, with the mouth of the V facing the exterior. It need only extend to 25 mm (1 in.) above the top of the closed window. You can do a better job if you first remove the stop and the bottom sash.

Top

Weatherstrip the space where the two sashes meet by removing the lower sash and applying V-type weatherstripping to the upper window from the inside.

Bottom

Apply V-type or compression-type neoprene rubber to the windowsill where the closed window will sit or to the bottom of the moving window sash itself.

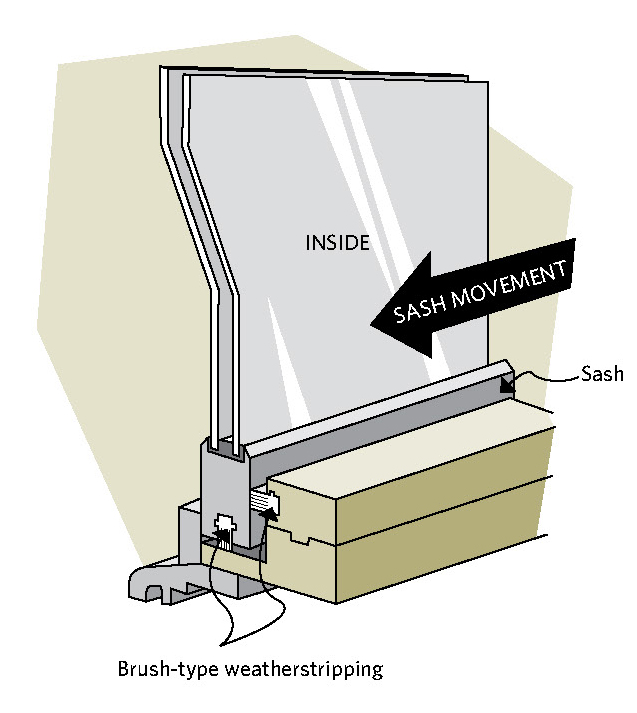

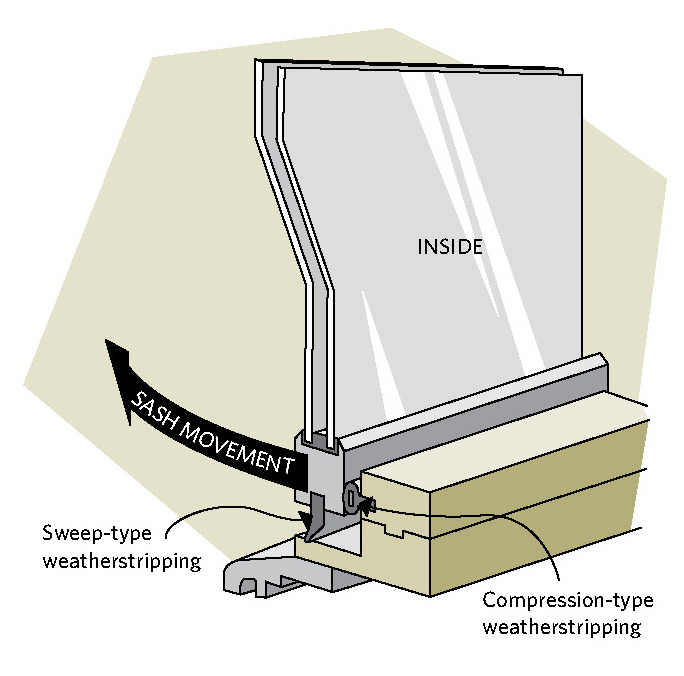

ii) Sliding windows

Sliding windows with sashes typically use brush weatherstripping that will require removing the sash and pulling the old weatherstripping out of its slot. Cut the new material to the length required and snap or slide it into the slot. Tack, staple or glue each end of the brush material to ensure that the weatherstripping stays in place before reinstalling the sash.

Sashless sliders – panes of glass not encased in a frame – are inefficient. At the very least they should be supplemented with interior storm windows. Better yet, replace them with energy-efficient units.

iii) Swing-type (hinged) windows

Swing-type (hinged) windows are treated like doors. Apply weatherstripping to the frame so it meets the edge of the sash or place it on the stop where it will meet the face of the sash. The force of a closed window against the weatherstripping makes a pressure seal. Hinged windows usually require a combination of V-strip and compression-type weatherstripping. Hinges and locking hardware may complicate the job. Sometimes, more than one weatherstrip will therefore be needed in those areas.

Storm window systems

Single-glazed windows lose about 10 to 20 times as much heat as the same area of a properly insulated wall. Storm windows or double-glazed sealed units will reduce the heat loss by almost half.

Storm windows can be installed on the inside or the outside, can be permanent or seasonal, and can be made to order.

Exterior storm window systems

Exterior storm windows were once very common and continue to serve a useful role in many applications. They are usually constructed of a wood or metal frame, with glass or an acrylic sheet as glazing.

Exterior storm windows can be either seasonal (installed in the fall and removed in the spring) or permanent. Seasonal storm windows should be inspected each year before installation to ensure that the glazing, putty and weatherstripping are in good condition. A drawback of seasonal units is the labour involved in installing and removing them each year, as well as the need for storage. Permanent exterior storm windows are usually equipped with a built-in screen and a sliding sash.

When you use exterior storm windows, the main interior window must be air sealed more tightly than the storm window to prevent moist household air from entering the space between the windows and being trapped, where it can condense and cause deterioration of the sash and frame.

Interior storm window systems

Interior storm windows are generally attached directly to the window frame, which helps reduce air leakage around the window. To minimize condensation and air leakage, interior storm windows should be sealed tightly so that no warm air gets between the storm unit and the original window after installation.

Interior storm windows are lighter and more accessible than seasonal exterior storm windows especially on upper floors. A disadvantage is that blinds or other window treatments may have to be repositioned to accommodate the storm window.

Interior storm windows are typically used in the winter only and are stored for the rest of the year. However, in an air-conditioned house, they can also help keep heat out and cool air in during the hot summer months.

There are two common interior storm window system options – heat-shrink film with double-sided tape and clear rigid acrylic sheets with magnetic seals.

Heat-shrink film with double-sided tape

These inexpensive, temporary, do-it-yourself kits are sold at most hardware and building supply stores and include in

structions for installation. With this system, two-sided tape attaches the film to the window trim, after which the film is heated with a hair dryer to shrink it tightly across the window. In most cases, the film can be used only once.

Although this system provides an excellent seal and good visibility, the two-sided tape can lift paint when it is removed. As well, once this system is installed, the window cannot be opened without removing or puncturing the film.

Points to keep in mind:

- Lightweight film may be damaged if you have young children or pets in the house.

- Plastics must be kept away from strong heat sources.

- Some people may be sensitive to plastics, which can emit odours, particularly when their surfaces are warmed by sunlight.

Clear rigid acrylic sheets with magnetic seals

This seasonal system is more durable than plastic film but more expensive; plus, it may require the services of a contractor. To install a magnetic seal system, a metal strip is fastened to the window trim using double-sided tape (this strip can be painted to match the frame). A magnetic moulding is then secured to the acrylic sheet and the sheet is pressed into place on the metal strip.

When the acrylic sheets are not in use, they must be stored in a flat or vertical position (not slanted) and in a cool place protected from exposure to sunlight and excessive heat. The rigid glazing is easier to clean and has a more finished appearance than shrink film.

Some plastic supply stores sell these systems (and the appropriate cleaning products) and can cut the sheets to the size required. As well, some firms specialize in manufacturing and installing these systems.

Specialty products

There are two products that are most suitable for areas that have very high solar gains that make the room too hot: applied window films and multi-layered polyester films. Films are usually professionally applied with some precautions.

Applied window films are usually made from a clear or tinted polyester substrate with a scratch-resistant coating on one side and an adhesive with a protective liner on the other. Multi-layered polyester films are black on one side and silver on the other. The film is permanently attached to the window by removing the liner and pressing it firmly on the glass.

Window films with a solar-control coating reduce solar gain and help protect carpeting, draperies, furniture and wood from fading. They should not be used on all windows as they offer very little increased insulation and greatly cut down on solar gain, which could lead to higher energy bills during the heating season.

There is also a small risk of glass breakage due to increased thermal stress and the use of these films may void the warranty issued by the original window manufacturer.

Curtains and blinds can help reduce radiant heat loss from windows during the heating season and reduce solar gain during the summer. Shutters, shades, awnings and trees can also reduce solar gains during the summer. Close window coverings during the day and open windows at night for ventilation.

During the heating season, insulated drapes offer somewhat more benefit than non-insulated drapes and blinds. However, as curtains and blinds are not airtight, they may cause window condensation problems in the winter.

Skylights

Skylights commonly suffer from water leakage and condensation around the frame and curb or tunnel. For operable skylights, ensure that hardware is working and all seals are in good order. Keep rain out by repairing exterior seals and flashings. Curbs and interior tunnels around the skylight must be well insulated and air sealed to reduce condensation. Reduce summer overheating with light-reflective glazing and blinds.

Do not open a skylight (or upper storey window) in hot weather if the house air temperature is cooler than the outside air. Opening the skylight draws hot air into the house, negating the effectiveness of air conditioning or natural cooling.

Information on buying new windows and doors

Helpful publications publications on energy-efficient windows and doors can be found at the Government of Canada Publications website.

DOORS

Poor installation, years of hard use, shifting foundations and seasonal warping can often force hinged doors and sliding glass patio doors to become out of square with their frames. If doors do not fit snugly, fix or replace the door, frame, hardware, gaskets and weatherstripping. The same techniques for preparing windows (as explained in Part 8.1, Windows) apply to all doors including any needed repairs or adjustments, surface preparation and cleaning for the weatherstripping.

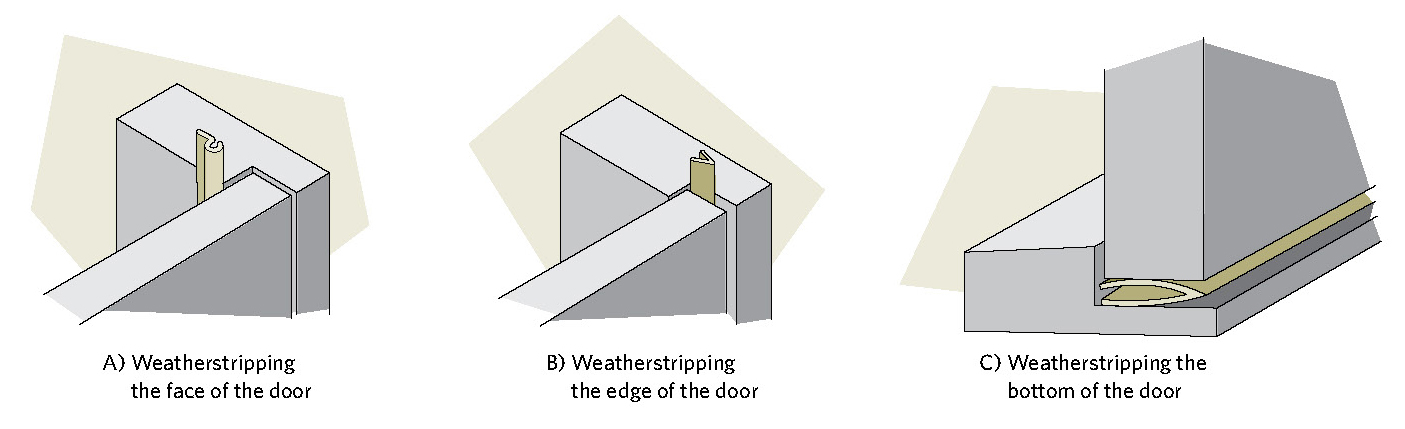

Weatherstrip the top and sides of the door frame as illustrated in Figure 8-8, Part A and Figure 8-8, Part B. The easiest and most effective weatherstripping for a door frame is a good quality V-shaped vinyl type. It makes contact with the edge of the door and provides a good seal even when the door warps from season to season.

For increased protection, attach weatherstripping to the stop so that it presses against the face of the door as shown in Figure 8-8, Part A.

There are also many types of combination metal and foam or rubber weatherstripping that are screwed to the stop. They should be adjusted regularly to conform to the changing warp of the door.

Apply weatherstripping to either the door sill (see the threshold in Figure 8-8, Part C) or to the door itself. Although this can be a difficult area to seal well, it is worthwhile doing because this is often a source of major drafts. Use durable material that can withstand traffic and is flexible enough to conform to changes in the door caused by fluctuations in humidity and temperature. The weatherstripping should also be easy to replace. A good seal can usually be obtained with gasketed door-bottom weatherstripping that attaches to the door, or with full or partial threshold weatherstripping that is attached to the door sill.

When the weatherstripping is applied to the door itself, a very durable material is necessary. The most effective choice is the combination type, which is simply tacked or screwed along the bottom inside surface of the door. There should be slots that allow for some adjustment of the weatherstripping.

There is a wide variety of door weatherstripping on the market, including kits that include weatherstripping and threshold or door bottom seals. Some products come with replacement seals. Look for high-quality, durable products.

For sliding patio doors, replace weatherstripping and hardware when worn. Replace poor condition sliding patio doors with ENERGY STAR® certified units or with French or garden-style doors and additional energy-efficient windows. In the interim, older patio sliding doors not used in winter can be sealed with removable sealant or covered with heat-shrink film.

Contracting the work

Air sealing and repairing windows and doors can become part of the work of an air sealing contractor (see Section 3, “Materials”). If you are having only some of the windows or doors replaced, ask the contractor to check and replace defective weatherstripping on the remaining units.

Window and door contractors

When getting estimates, make sure the contractor has experience in the type of work you want done. Ask the contractor if the company offers a third-party warranty on products and services.

Contact Us Today For Sales And Installation.

+1 (800) 282-9544

Do Not Replace Your Windows! Insulate them with Magnetite Canada for a fraction of the cost of new windows.

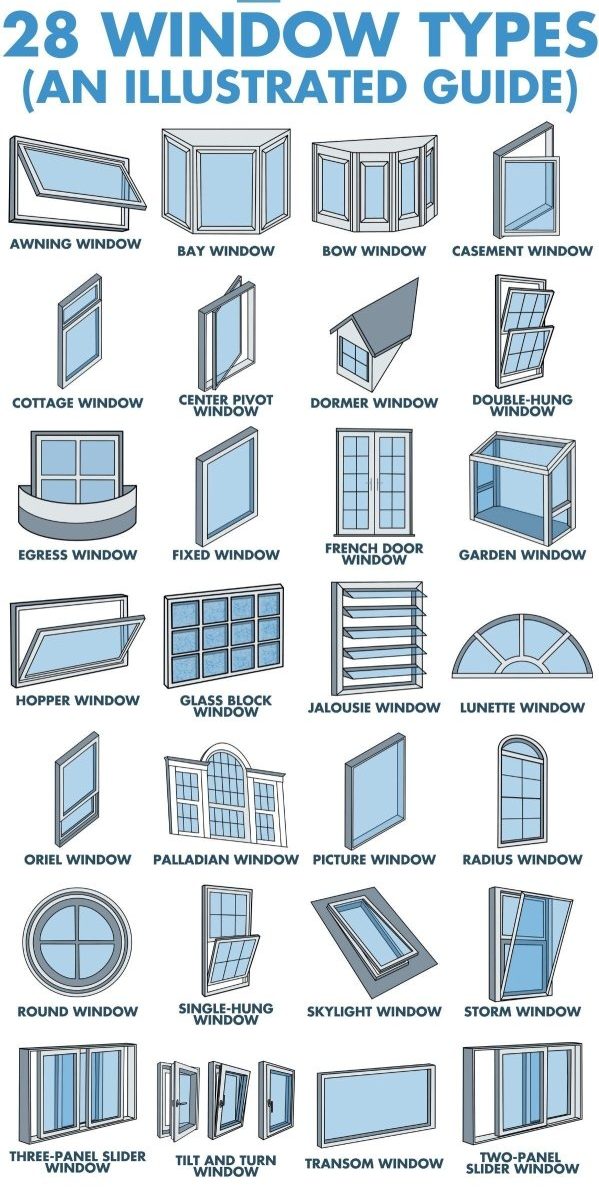

What Kind of Window Do You Have?